Harddrive-engineerguy

Hard drive teardown. Bill tears down a hard drive to show how it stores data. He explains how smooth the disk surface must be for the device to work, and he outlines the mathematical technique used to increase data storage.

Transcript

|

|---|

|

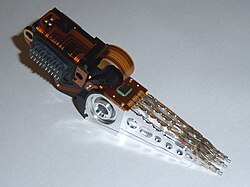

A home computer is a powerful tool, but it must store data reliably to work well, otherwise its kind of pointless isn't it? Let's look inside and see how it stores data. Look at that: It's marvelous! It's an ordinary hard drive, but its details, of course, are extraordinary. Now, I'm sure you know the essence of a hard drive: We store data on it in binary form - ones and zeros. Now, this arm supports a "head" - which is an electro-magnet that scans over the disk and either writes data by changing the magnetization of specific sections on the platter or it just reads the data by measuring the magnetic polarization. Now, in principle, pretty simple, but in practice a lot of hard core engineering. The key focus lies in being sure that the head can precisely - error free - read and write to the disk. The first order of business is to move it with great control. To position the arm engineers use a "voice coil actuator". The base of the arm sits between two powerful magnets. They're so strong they're actually kind of hard to pull apart. There. The arm moves because of a Lorentz force. Pass a current through a wire that's in a magnetic field and the wire experiences a force; reverse the current and the force also reverses. As current flows in one direction in the coil the force created by the permanent magnet makes the arm move this way, reverse the current and it moves back. The force on the arm is directly proportional to the current through the coil which allows the arm's position to be finely tuned. Unlike a mechanical system of linkages there is minimal wear and it isn't sensitive to temperature. At the end of the arm lies the most critical component: The head. At its simplest it's a piece of ferromagnetic material wrapped with wire. As it passes over the magnetized sections of the platter it measures changes in the direction of the magnetic poles. Recall Faraday's Law: A change in magnetization produces a voltage in a nearby coil. So, as the head passes a section where the polarity has changed it records a voltage spike. The spikes - both negative and positive - represent a "one" and where there is no voltage spike corresponds to a "zero." The head gets astonshingly close to the disk surface - 100 nanometers in older drives, but today under ten nanometers in the newest ones. As the head gets closer to the disk its magnetic field covers less area allowing for more sectors of information to be packed onto the disk's surface. To keep that critical height engineers use an ingenious method: They "float" the head over the disk. You see, as the disk spins it forms a boundary layer of air that gets dragged past the stationary head at 80 miles per hour at the outer edge. The head rides on a "slider" aerodynamically designed to float above the platter. The genius of this air-bearing technology is its self-induced adjustment: If any disturbance causes the slider to rise too high it "floats" back to the where it should be. Now, because the head is so close to the disk surface any stray particles could damage the disk resulting in data loss. So, engineers place this recirculating filter in the air flow; it removes small particles scraped off the platter. To keep the head flying at the right height the platter is made incredibly smooth: Typically this platter is so smooth that it has a surface roughness of about one nanometer. To give you an idea of how smooth that is let's imagine that this section is enlarged until it's as long as a football field - American or International - the average "bump" on the surface would be about three hundredths of an inch. The key element of the platter is the magnetic layer, which is cobalt - with perhaps platinum and nickel mixed in. Now this mixture of metals has high coercivity, which means that it will maintain that magnetization - and thus data - until it is exposed to another powerful magnetic field. One last thing that I find enormously clever: Using a bit of math to squeeze up to forty percent more information on the disk. Consider this sequence of magnetic poles on the disk's surface - 0-1-0-1-1-1. A scan by the head would reveal these distinct voltage spikes - both positive or negative for the "ones." We would be easily able to distinguish it from, say, this similar sequence. If we compare them they clearly differ. Engineers, though, always work to get more and more data onto a hard drive. One way to do this is to shrink the magnetic domains, but look what happens to the voltage spikes when we do this. For each sequence the spikes of the ones now overlap and superimpose giving "fuzzy" signals. In fact, the two sequences now look very similar. Using a technique called Partial Response Maximum Likelihood engineers have developed sophisticated codes that can take a murky signal like this, generate the possible sequences that could make it up and then choose the most probable. As with any successful technology, these hard drives remain unnoticed in our daily lives, unless something goes wrong! I'm Bill Hammack, the engineer guy. |

Relevante Bilder

Relevante Artikel

FestplattenlaufwerkEin Festplattenlaufwerk, früher auch Festplatten-Speichersystem oder Festplatten-System, oft auch als Festplatte oder Hard Disk bezeichnet, ist ein magnetisches Speichermedium der Computertechnik, bei welchem Daten auf die Oberfläche rotierender Scheiben geschrieben werden. Zum Schreiben wird die hartmagnetische Beschichtung der Scheibenoberfläche entsprechend der aufzuzeichnenden Information berührungslos magnetisiert. Durch die Remanenz erfolgt das Speichern der Information. Das Lesen der Information erfolgt durch berührungsloses Abtasten der Magnetisierung der Plattenoberfläche. .. weiterlesen