Differenzgewinde

Differenzgewinde (auch Differentialgewinde) bezeichnet die Kombination zweier gewöhnlicher Gewinde mit unterschiedlicher Steigung, die sich auf einer gemeinsamen Achse befinden. Bei der Rotation dieser Achse führen die auf den beiden Gewinden sitzenden Bauteile eine Relativbewegung zueinander durch, die der Differenz der Steigungen entspricht. Dies ermöglicht eine sehr genaue Einstellung des Abstands zwischen beiden Bauteilen, die sonst nur mit einem sehr feinen Gewinde möglich wäre, das eine entsprechend geringe mechanische Stabilität besäße.

Eine Schraube mit Differenzgewinde ermöglicht auch ein platzsparendes und festes Verspannen von Bauteilen. Die Schraube besitzt – in verschiedenen Bereichen ihres Schaftes – zwei Gewinde mit gleicher Gangrichtung, aber unterschiedlicher Steigung P. Auch der Gewindedurchmesser ist frei wählbar. Beim Verspannen der Bauteile gegeneinander wirkt die Schraube mit Differenzgewinde wie eine normale Schraube, deren Gewindesteigung die Differenz beider Steigungen – also relativ klein – ist.

Je kleiner die Steigungsdifferenz (bei gleichem Anziehdrehmoment) ist, desto größer sind die Spannkräfte.

Analog können auch Muttern mit Differenzgewinde ausgestaltet werden.

Anwendungen

- Werkzeugaufnahme von Wendeschneidplatten (Drehmaschine)

- Selten an Pleueln in Hubkolbenmotoren, falls das untere Pleuelauge geteilt ist

- Spannschraube an Morsekonus-Werkzeughalterungen (z. B. Wabeco)

Siehe auch

siehe auch: Gewinde (für die Begriffe: Steigung oder Gangrichtung)

Auf dieser Seite verwendete Medien

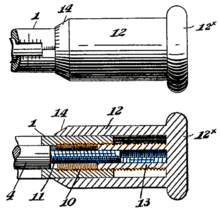

Exterior and cutaway drawing of micrometer adjustment mechanism from US patent 585184[1].

Legend

1 - Main barrel

4 - Adjusting rod (a tab on the rod, not shown, fits into a slot on the barrel to prevent them from rotating relative to each other; they are confined to sliding in and out)

10 - Female screw cut into tube 1 (orange); the example uses a right hand, 20 threads per inch (tpi) pitch

11 - Male screw cut onto rod 4 (blue); the example uses a right hand, 25 tpi thread

12 - Sleeve cap or thimble

12x -Milled bead on thimble

13 - Nut sleeve with, for example, outer 20 tpi threads (orange) and inner 25 tpi threads (blue); fixed attachment to sleeve cap 12

14 - Beveled end of sleeve cap with ruler markings to show rotational movement

Each full rotation of the thimble + nut sleeve, 12 + 13, moves the rod 0.01 in (0.25 mm) relative to the main barrel due to the differential motion from the 20 tpi and 25 tpi threads.

- ↑ US patent 585184 (1897-06-29) Clarke, George R. Calipers

Differential Screw illustration - Figure D3, Plate 1[1]

“A method of converting circular into rectilinear motion with an extremely low velocity has been discovered by M. Prony. It is by means of this contrivance that we are enabled to avoid the necessity of using screws of an unusually fine thread, to procure a slow adjusting motion. The disadvantages arising from the use of such screws were formerly very great; the rapid wear and consequent inaccuracy of the usual micrometers was an instance of the ill consequences produced by that circumstance. It is also capable of many other practical and useful applications. The original idea of the inventor is extremely simple and elegant.

AB is an axis or spindle divided into three portions ab, cd, ef. The two screws ab, ef are of the same thread: they pass through the two fixed supports CD, in each of which there is a nut; the spindle has an horizontal motion, and at each revolution of the screw moves over a space equal to one of its threads; the portion cd; is formed into another screw, the thread of which may either be a little finer or a little coarser than that of the screws ab, ef, and the difference may be small at pleasure. A nut M is introduced, in which the threads of a micrometer are fixed: this nut being checked by the block EF, is not at liberty to turn with the spindle AB, which it would otherwise do: but at each revolution of the spindle moves a space equal to one of its own threads, its rate of motion is therefore compounded of the actual and relative advance of the spindle AB: so that it really moves but the amount of the difference between those motions.

This is M. Prony’s simple and ingenious solution of this problem.

In practice, it will be found difficult to make the two screws ab, and ef so accurately alike, that there shall be no resistance in the nuts: one of these might however be omitted, that portion of the spindle being in that case made plain or cylindrical.”- ↑ M.M. Lanz & Betancourt, translated from the original French by Lanz, Philippe Louis (1817) Analytical essay on the construction of machines, London: R. Ackermann, S. text pg. 14−15, drawing pg. 181 Plate 1 fig D3

Autor/Urheber: +- in der Wikipedia auf Japanisch, Lizenz: CC BY-SA 3.0

Rotating one screw with two nuts that each have a slightly different thread pitch changes the distance between the nuts only by the difference in the pitches.

Differenzgewinde, die Differenz der Steigung P1 − P2 erzeugt die Spannkraft.